Drying machine

LIMA Fish Feed Machine,Chicken Feed Machine

Drying machine is one of the most important steps in the processing of extruded feed. The moisture content of the feed pellets just extruded from the feed extruder is very high, reaching more than 22%. It must be equipped with dryer to remove more than 10% of the moisture and then be cooled to ensure that it can reach qualified product quality.

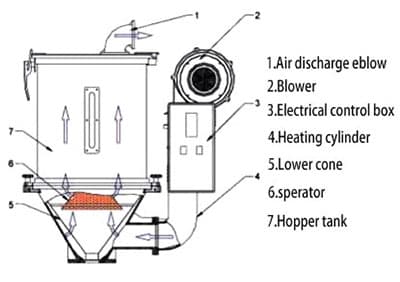

The drying machine in the feed processing of the extruder mostly adopts the conveyor belt and the chain plate box dryer. Small Fish feed production line is normally adopting the vertical drying machine with self-priming. And in the feed pellet line, dryer is generally used with cooler for processing feed pellets.

Features of Dryer machine

1. Small investment, fast drying speed and high evaporation intensity.

2. High efficiency, high output and good product quality.

3. Standardized production can increase the number of stages according to the output.

4. It can adjust the air volume, heating temperature, material residence time and feeding speed to achieve the best

drying effect.

5. The equipment configuration is flexible. The belt washing system and material cooling system can be used.

6. Most of the air is recycled to save energy.

7. Unique air distributor makes the hot air distribution more uniform and ensures the consistency of product quality.

8. Heat source can be matched by steam, heat conducting oil, point or gas hot blast stove.

Dryer machine main technical parameters

| Model | LM-1 | LM-3 | LM-7Ⅰ | LM-7Ⅱ | LM-9 |

| Power (kw) | 15-18 | 24 | 27 | 36 | 45 |

| Capacity (kg/h) | 150-200 | 300-400 | 500-600 | 1-1.5T | 2-2.5T |

| Size (cm) | 320*110*155 | 400*135*215 | 450*150*240 | 580*150*240 | 650*210*240 |

- Receiving of feed raw materials

- Nutritional value and processing technology of corn straw

- Best feed mixture processing process

- How to solve the poultry manure pollution?

- Why do the poultry Farmers choose the Supplementary feeding strategie?

- Poultry And Livestock Farmings Affect The Environment

- Why choose the Nutrition Feed For poultry instead of traditional feedstuffs?

- Why choose extruder to produce fish feed?

- 100kg – 500kg floating fish feed line

- Small Chicken Feed Mill Plant

Products

- 100kg – 500kg floating fish feed line

- Small Chicken Feed Mill Plant

- Small Scale Fish Feed Pellet Line 60kg – 150kg/h

- Diesel Engine Animal Feed Machine

- Diesel Engine Dry Type Fish Feed Extruder Machine

- Wet Type Fish Feed Machine Extruder

- Dry Type Fish Feed Extruder Fish Feed Machine

- Auger screw elevator

- Ring die feed pellet making machine

- Flat die feed pellet mill

NEWS

- LIMA Machinery Participated in the Pakistan Exhibition

- 2019 LIMA Machinery Participated in the Nigeria Agriculture Exhibition

- 2018 LIMA Machinery Participated in the Nigeria Exhibition

- LIMA Machinery Participated in the 126th Canton Fair

- LIMA Machinery Participated in the 125th Canton Fair

- 2016 Participated in the Canton Fair