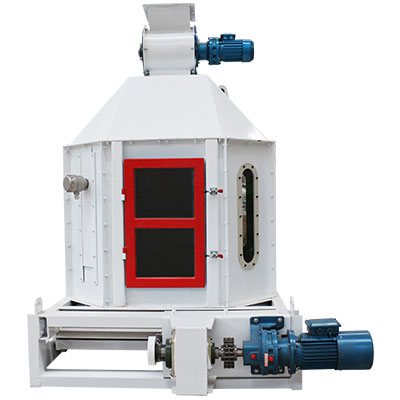

Feed cooler machine

LIMA Fish Feed Machine,Chicken Feed Machine

Structure of Feed cooler machine

A Feed cooler machine is a machine that achieves refrigeration through vapor compression or absorption cycles. These liquids can flow through heat exchangers for the purpose of cooling air or equipment. Vapor compression chillers consist of four main components of a vapor compression refrigeration cycle (in the form of compressors, evaporators, condensers, and partial metering devices). The machine can realize different refrigerants, the refrigerant used in absorption refrigerators and the benign silica gel used in urban water as desiccant. Absorption refrigerators use water as a refrigerant and rely on a strong affinity between water and lithium bromide solution to achieve a cooling effect.

One the principle of the advanced counter flow cooling ,SKLN Series counter flow cooler is equipped with a reciprocating grate type discharging device, which is characterized by its smooth material flowing and uniform discharging.

The octagon cooling bin has eliminated dead cooling corner, which is beneficial to the cooling treatment of materials.

The cooled pellet is≤3℃-5℃ of the room temperature

SKLN series counter-flow cooler is suitable for cooling various kinds of pellets such as pelleted feed, expanded feeds, extruded feeds and flake feeds, etc. It is normally used for feed pellet machine and feed pellet industries. The large feed manufacturers need the cooler for easy to transporting pellets and used for feed production line.

Feed cooler machine main technical specifications

| Model | Capacity (T/H) |

Time (min) |

Temperature | Precipitation rate |

Pressure (Pa) |

Air absorption |

Main power |

Feed power |

| SKLN11 | 1-2 | 10-15 | +3℃-+5℃ | ≥3%-3.5% | 2000 | 34m³/min | 1.5kw | 0.75kw |

| SKLN15 | 4-5 | 10-15 | +3℃-+5℃ | ≥3%-3.5% | 2000 | 34m³/min | 1.5kw | 0.75kw |

| SKLN19 | 10-15 | 10-15 | +3℃-+5℃ | ≥3%-3.5% | 2000 | 34m³/min | 1.5kw | 0.75kw |

| SKLN22 | 16-20 | 10-15 | +3℃-+5℃ | ≥3%-3.5% | 2000 | 34m³/min | 1.5kw | 0.75kw |

Working principle of feed cooler machine

The dry wet material is sent to the hopper by the belt conveyor or the bucket elevator, and then enters the feeding end through the feeding pipeline through the feeding machine of the hopper. The inclination of the feeding pipeline should be greater than the natural inclination of the material, so that the material can flow into the cooler smoothly. The cooler cylinder is a rotating cylinder slightly inclined to the horizontal. The material is added from the higher end, the heat carrier flows out from the low end, and is in countercurrent contact with the material, and some heat carrier and material flow into the cylinder together. With the rotation of the cylinder, the material runs to the bottom end by gravity. During the forward movement of the wet material in the cylinder, the heat is directly or indirectly supplied by the heat carrier, so that the hot material is cooled, and then sent out through a belt conveyor or a screw conveyor at the discharge end. A copy board is installed on the inner wall of the cylinder, and its function is to copy and sprinkle the material, so that the contact surface between the material and the air flow increases, so as to improve the cooling rate and promote the advancement of the material. The cooling body is generally divided into cold air and the like. After the heat carrier passes through the cooler, a cyclone dust collector is generally required to capture the materials in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should also be discharged after passing through a bag filter or a wet filter.

- Receiving of feed raw materials

- Nutritional value and processing technology of corn straw

- Best feed mixture processing process

- How to solve the poultry manure pollution?

- Why do the poultry Farmers choose the Supplementary feeding strategie?

- Poultry And Livestock Farmings Affect The Environment

- Why choose the Nutrition Feed For poultry instead of traditional feedstuffs?

- Why choose extruder to produce fish feed?

- 100kg – 500kg floating fish feed line

- Small Chicken Feed Mill Plant

Products

- 100kg – 500kg floating fish feed line

- Small Chicken Feed Mill Plant

- Small Scale Fish Feed Pellet Line 60kg – 150kg/h

- Diesel Engine Animal Feed Machine

- Diesel Engine Dry Type Fish Feed Extruder Machine

- Wet Type Fish Feed Machine Extruder

- Dry Type Fish Feed Extruder Fish Feed Machine

- Auger screw elevator

- Ring die feed pellet making machine

- Flat die feed pellet mill

NEWS

- LIMA Machinery Participated in the Pakistan Exhibition

- 2019 LIMA Machinery Participated in the Nigeria Agriculture Exhibition

- 2018 LIMA Machinery Participated in the Nigeria Exhibition

- LIMA Machinery Participated in the 126th Canton Fair

- LIMA Machinery Participated in the 125th Canton Fair

- 2016 Participated in the Canton Fair